We actively incorporate Micro Channel Corrosion Protection into our business strategy. The development of the Micro Channel Heat Exchanger (MCHE) originated from the automotive industry and spans over twenty years. However, it has only recently made its way into the HVAC&R industry. Notable advantages include their lightweight nature, improved efficiency, and reduced required refrigerant volume. Additionally, MCHE coils, constructed of aluminum, are less susceptible to galvanic corrosion compared to traditional RTPF coils.

Furthermore, MCHE coils not only offer the mentioned benefits but also present additional challenges. In corrosive environments, both the fins and the aluminum tubes are at risk of corrosion.

Blygold PoluAl MC: flexible coating & flexible application process

Coating flexibility

The Blygold PoluAL MC coating exhibits flexibility. Even after undergoing thermal cycle testing, the coating can withstand fin bending without the risk of cracking or delamination. Additionally, this coating’s flexibility allows flat micro channel coils to be bent after application. Tests have demonstrated that the coating remains in perfect condition on the bent areas.

Application flexibility

Blygold applies PoluAl MC using its special spray techniques, enhancing the flexibility of the application process. Consequently, it can be applied to any size of micro channel heat exchanger without restrictions. Moreover, coils that are already bent can also undergo treatment with PoluAl MC.

HVAC corrosion protection

Blygold has developed pioneering new coatings specifically designed for HVAC corrosion protection. Since its inception, Blygold has consistently prioritised corrosion protection for heat exchangers, which are susceptible to severe corrosion due to their construction with dissimilar metals and exposure to air circulation pollution.

The success of these protective corrosion products can be attributed to their unique application method, which includes applying a thin layer and possessing high UV and chemical resistance properties. These renowned products have gained global recognition in the air conditioning industry. Blygold takes pride in its extraordinary success stories and is honoured to have contributed to ambitious projects such as the cruise ship Queen Mary 2, Palm Island Jumeirah, and London Heathrow Airport.

Great for you

- Preserves high efficiency of micro channel HX

- Prevents early micro channel HX failure

- Heat conductive protective layer

- Improved water release properties

- Highly flexible for coil bending

- Reflective pigment prevents sun radiation absorption

- 11,000 hour salt spray test ASTM B117

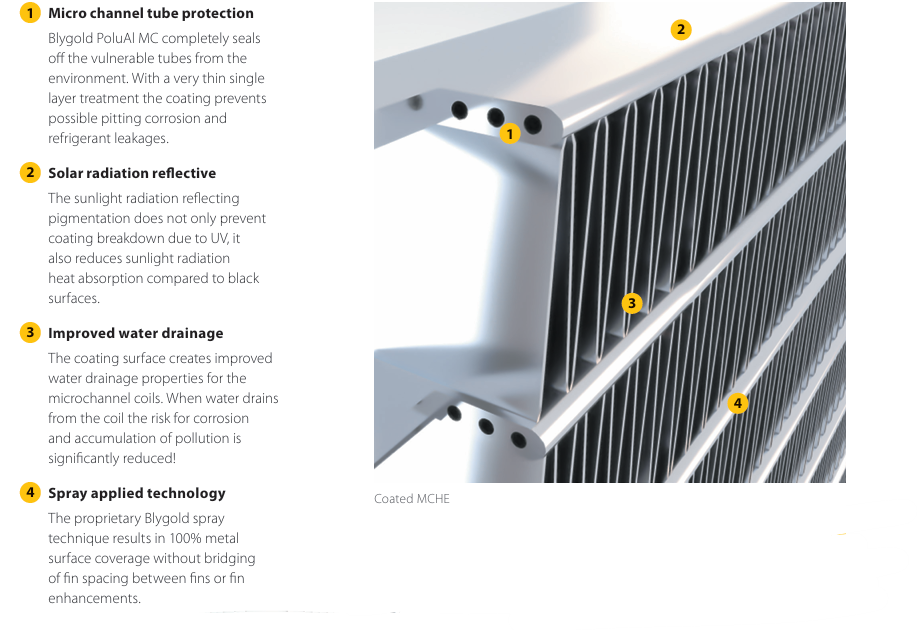

Blygold PoluAl MC completely seals off the vulnerable tubes from the environment. With a very thin single layer treatment the coating prevents possible pitting corrosion and refrigerant leakages. The sunlight radiation reflecting pigmentation does not only prevent coating breakdown due to UV, it also reduces sunlight radiation heat absorption compared to black surfaces.

The coating surface creates improved water drainage properties for the microchannel coils. When water drains from the coil the risk for corrosion and accumulation of pollution is significantly reduced!

The proprietary Blygold spray technique results in 100% metal surface coverage without bridging of fin spacing between fins or fin enhancements.

See our sheet on Micro Channel Corrosion Protection, below.

Looking for some industry HVAC news? Try the link, below.

Blygold is an ISO 9001:2015 Certified Company