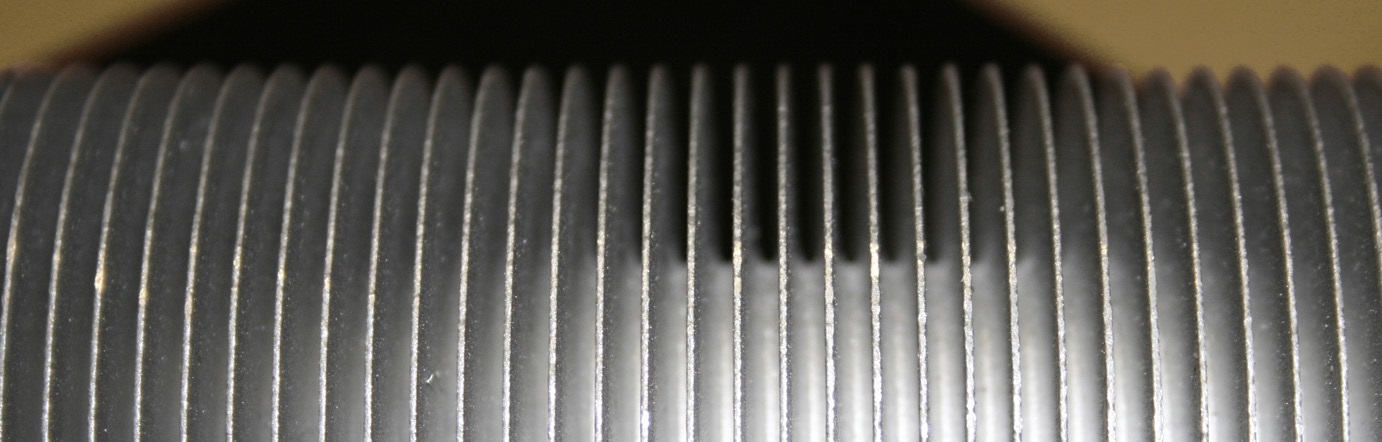

Finned Tube Corrosion Protection

Finned Tube Corrosion Protection is key to prevent corrosion.

These aluminium fins improve fluid transfer outside the tube, typically for air or gas, with crossflow, counterflow, or parallel flow patterns.

Fins compensate for the low air-side heat transfer coefficient, increasing the surface area for heat transfer.

Aluminium, chosen for its excellent heat conductivity, ensures efficient heating compared to other materials.

These heat exchangers find wide use in power plants, offshore rigs, and heavy industries.

While known for quality, they may require extra protection in corrosive environments.

To protect vulnerable metals, Blygold developed specialized coatings for spiral tube bundles.

These coatings can be applied to various fin tubes before or after assembly using special Blygold spray procedures, ensuring full coverage even within thick and complex elements. All Blygold coatings undergo comprehensive testing to assess their impact on heat transfer, pressure drop, corrosion, and chemical resistance. Customers can trust that coated bundles will deliver long-lasting performance.

Moreover, Blygold offers solutions to safeguard aluminium against harsh conditions, even for heat recovery coils.

Blygold PoluAl

One of our most sought-after products is PoluAl XT, an aluminum pigmented polyurethane coating designed to protect air-cooled heat exchangers. This product fulfills all the necessary requirements for coating Finned Tube heat exchangers. PoluAl XT distinguishes itself from others by its outstanding chemical and UV resistance. Additionally, it provides flexibility, excellent adhesion, and minimal impact on heat transfer. Furthermore, it can be applied in an exceptionally thin layer to mitigate pressure drop.

High Temperatures

Blygold PoluAl High Temp is a heat-conducting, corrosion-prohibitive coating capable of safeguarding metals from rapid deterioration under extreme conditions and enduring temperatures up to 650°C (1202°F). This coating prevents capacity loss and premature deterioration of the heat exchanger. When applied by qualified Blygold applicators, this protection system guarantees energy recovery and optimal performance.

Great for you

– Withstands high chemical exposure

– Heat resistance extends up to 650°C (1202°F)

– Triples the lifespan of equipment

– Incurs negligible pressure drop

– Suitable for both factory and field operation

– Provides heat-conductive corrosion protection

Each Blygold product is custom-made to address the specific requirements of the client. Blygold takes pride in delivering energy-efficient and cost-effective solutions to meet the demands of today’s corrosion protection market.

Looking for some industry HVAC news? Try the link, below.

Blygold is an ISO 9001:2015 Certified Company