What are the types of HVAC Corrosion?

Identification of HVAC Corrosion is relatively simple. Typically, general corrosion arises when the majority or all atoms on a metal surface undergo oxidation, resulting in damage across the entire surface. Most metals readily oxidize, losing electrons to oxygen (and other substances) present in the air or water. As oxygen undergoes reduction (gains electrons), it combines with the metal to form an oxide.

1. Galvanic Corrosion: (also called dissimilar metal corrosion or bimetallic corrosion)

Galvanic corrosion occurs when two dissimilar metals are in contact with each other in the presence of an electrolyte, such as moisture or condensation. In HVAC systems, galvanic corrosion often occurs between aluminium and copper components, which have different electrochemical potentials. This leads to the accelerated corrosion of one metal (usually aluminium) while the other metal (copper) remains relatively unaffected.

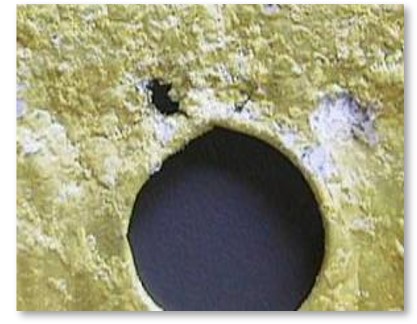

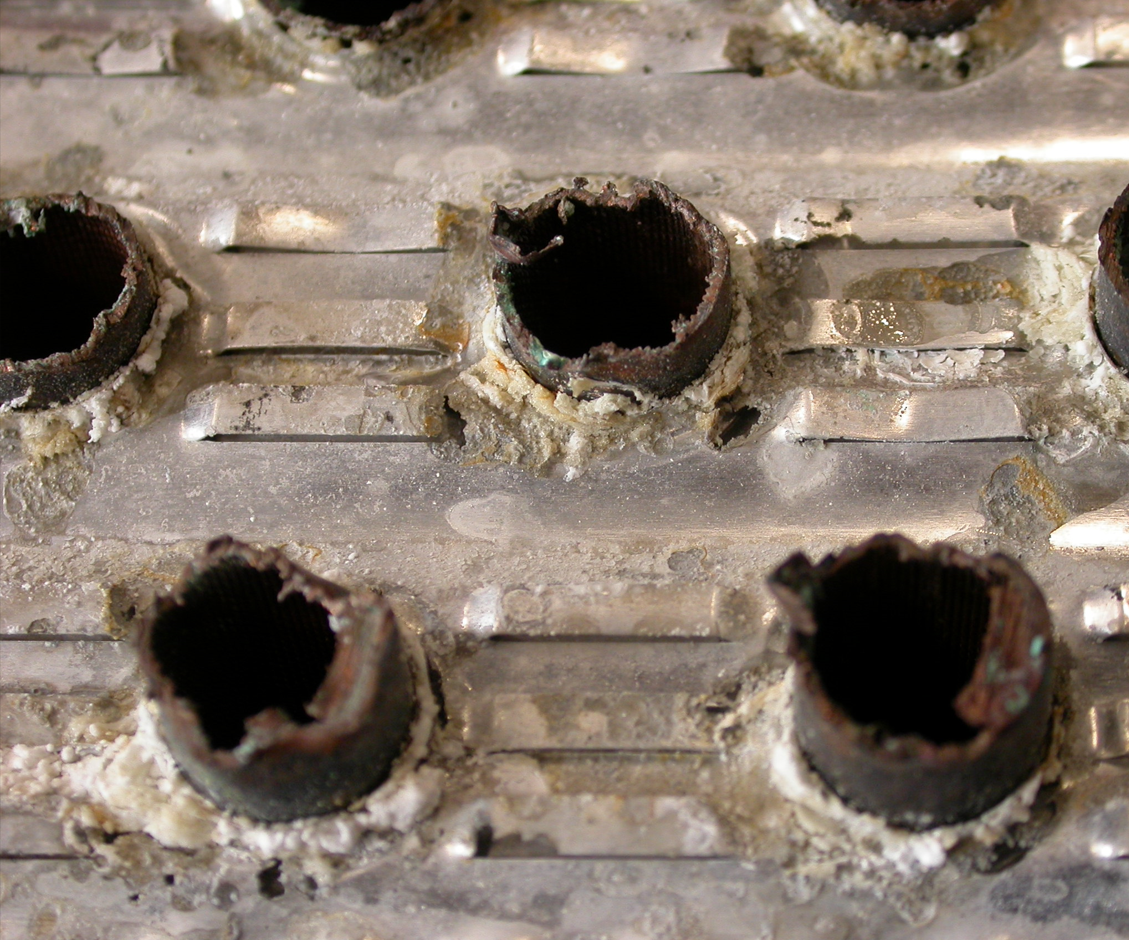

2. Pitting Corrosion:

Pitting corrosion is a localised form of corrosion characterised by the formation of small pits or craters on the surface of metal components. It occurs when small imperfections or defects in the protective oxide layer on the metal surface allow corrosive agents to penetrate and attack the underlying metal. Pitting corrosion can weaken HVAC components and lead to structural damage if left untreated. Pitting is considered to be more dangerous than uniform corrosion damage because it is more difficult to detect, predict and design against.

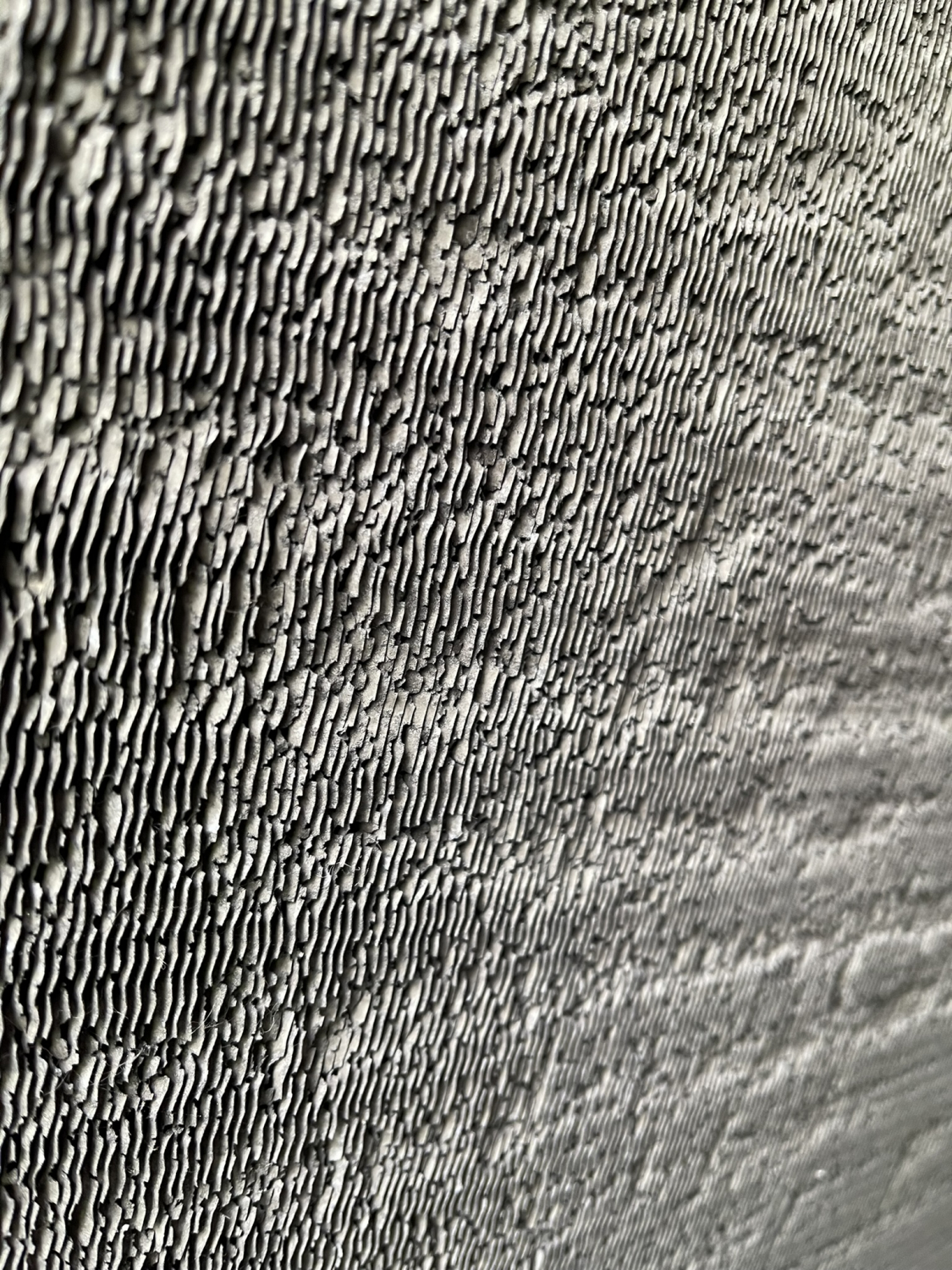

3. Filiform Corrosion:

Filiform corrosion is a type of corrosion that occurs beneath protective coatings, such as paint or powder coatings. It appears as thin, thread-like filaments or tunnels spreading beneath the coating surface. Filiform corrosion is particularly problematic in humid environments where moisture can penetrate the coating and initiate corrosion on the metal substrate. In HVAC systems, filiform corrosion can compromise the integrity of painted or coated aluminium and copper components.

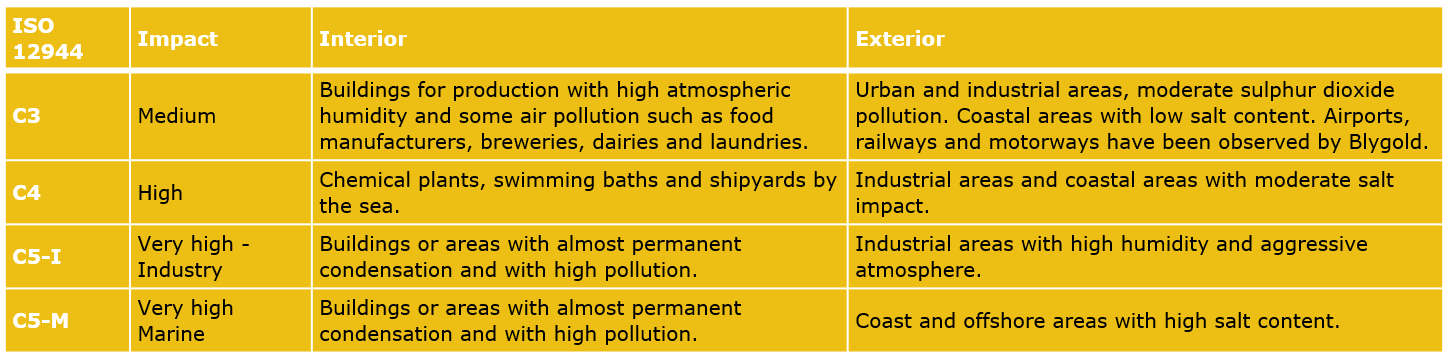

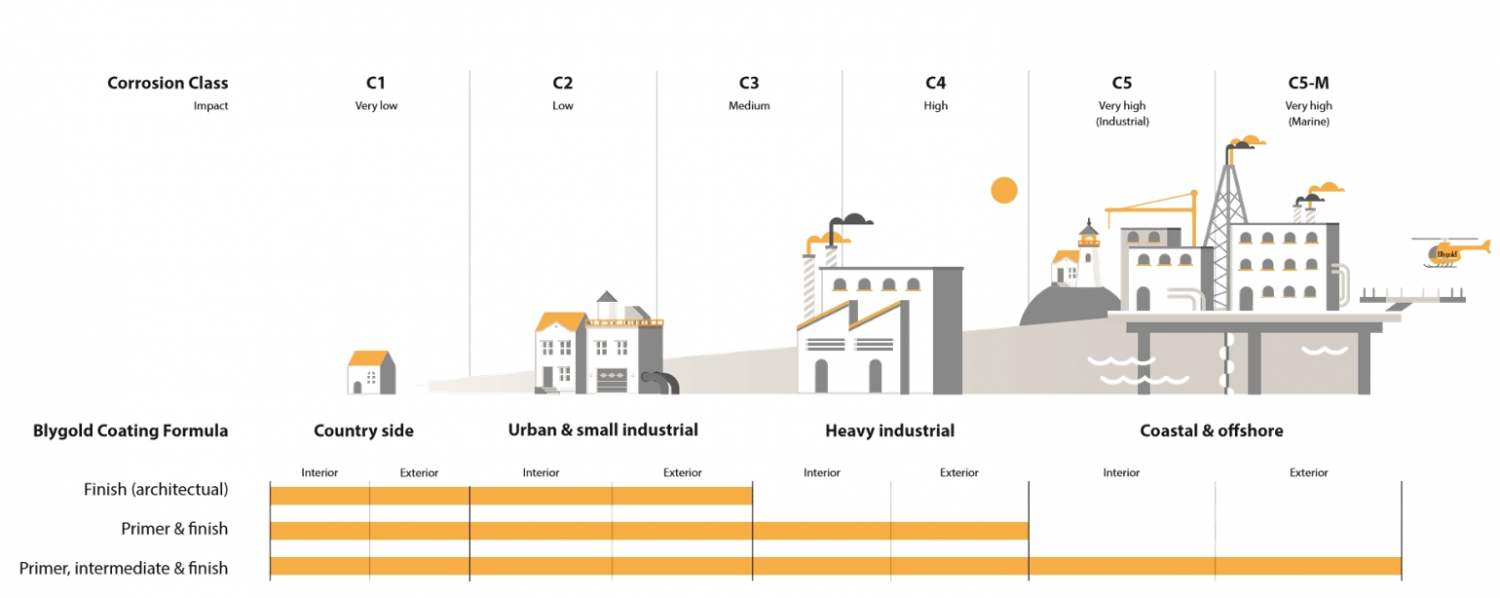

ISO 12944 Corrosion Classes

Identification of HVAC Corrosion. Factors that determine corrosivity of the environment include temperature, humidity, condensation, and corrosive pollutants in the atmosphere.

Identification of HVAC Corrosion from low to high levels

In summary, identification of HVAC Corrosion in the early stages is paramount so protective action can take place.

Looking for some industry HVAC news? Try the link, below.

Blygold is an ISO 9001:2015 Certified Company